Is

that possible that one day the world could be completely reliant on

solar energy? To answer this question, we first need to examine how

solar panels work.

What are solar panels?

Solar panels (also known as PV modules) are the core component of the solar power system.

It directly influences the power efficiency of the solar power plant. A

single solar panel consists of many small PV cells. Each cell is made

of crystalline silicon, which can work as a semiconductor. When solar

panels are exposed to sunlight, they convert sunlight energy into

electricity.

How do solar panels work?

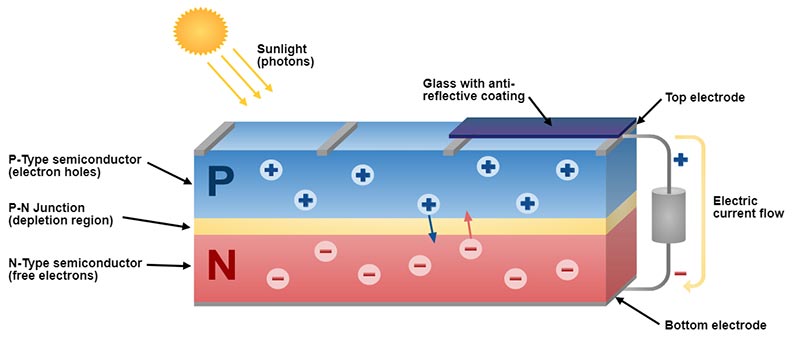

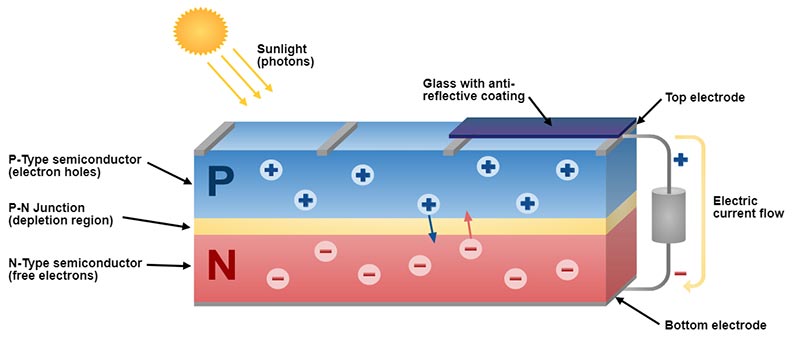

Solar

panels consist of smaller units called solar cells. The mainstream

solar cells are made from Silicon. It is a semiconductor that is the

second most abundant element on Earth. A solar cell is sandwiched

between conductive layers. Each silicon atom is connected to its

neighbors by four strong bonds which keep the electrons in place so that

no current can flow. What’s the key? A silicon solar cell has two

different layers of silicon, N-type silicon has extra electrons and

P-type silicon has extra spaces for electrons, called holes. Where the

two types of silicon meet, electrons can wander across the P/N junction,

leaving a positive charge on one side and creating a negative charge on

the other.

You

can think of light as the flow of tiny particles called photons,

shooting out from the sun. When one of these photons strikes the silicon

cells with enough energy, it can knock an electron from its bond,

leaving a hole. The negatively charged electrons and location of the

positively charged holes are now free to move around. But because of the

electric field at the P/N junction, they’ll only go one way. The

electron is drawn to the N-side, while the hole is drawn to the P-side.

The mobile electrons are collected by thin metal fingers at the top of

the cell. From there, they flow through an external circuit, doing

electrical work, like powering a light bulb, before returning through

the conductive aluminum sheet on the back. Each silicon cell only puts

out half a volt, but you can string them together in modules to give

more power.

You can read more about the specifics of the how solar panels work in this blog post if you want to learn more.

Types of solar panel

Currently, there are three types of solar panels in common according to the PV cells: monocrystalline solar panels, polycrystalline PV modules, and thin film solar panels.

A

monocrystalline photovoltaic panel is made of high-purity

monocrystalline silicon rods, which are widely used in the photovoltaic

industry and have a high photoelectric conversion rate; the four corners

of monocrystalline PV cells are rounded, and their color is nearly

black; besides, the crafts of monocrystalline cells are more complex and

thus the cost is higher.

Polycrystalline photovoltaic

modules component of polycrystalline solar cells arrayed in various

series and parallel configurations. The four corners of the PV cells are

square. Moreover, it is colored sky blue, and the cost of the poly

solar panel is lower compared to mono panels.

The

thin-film solar panel is made of thin films of semiconductors deposited

on glass, plastic, or metal. The films are incredibly thin, often 20

times thinner than c-Si wafers. This makes thin-film solar panels

flexible and lightweight. It has high power efficiency under certain

situations, like under shading or high temperature.

Conclusion Solar

power is getting better, cheaper, and competing with the electricity

from the grid. And innovations, like Topcon cells and HJT cells, may

bring solar panels a brighter future.